Description

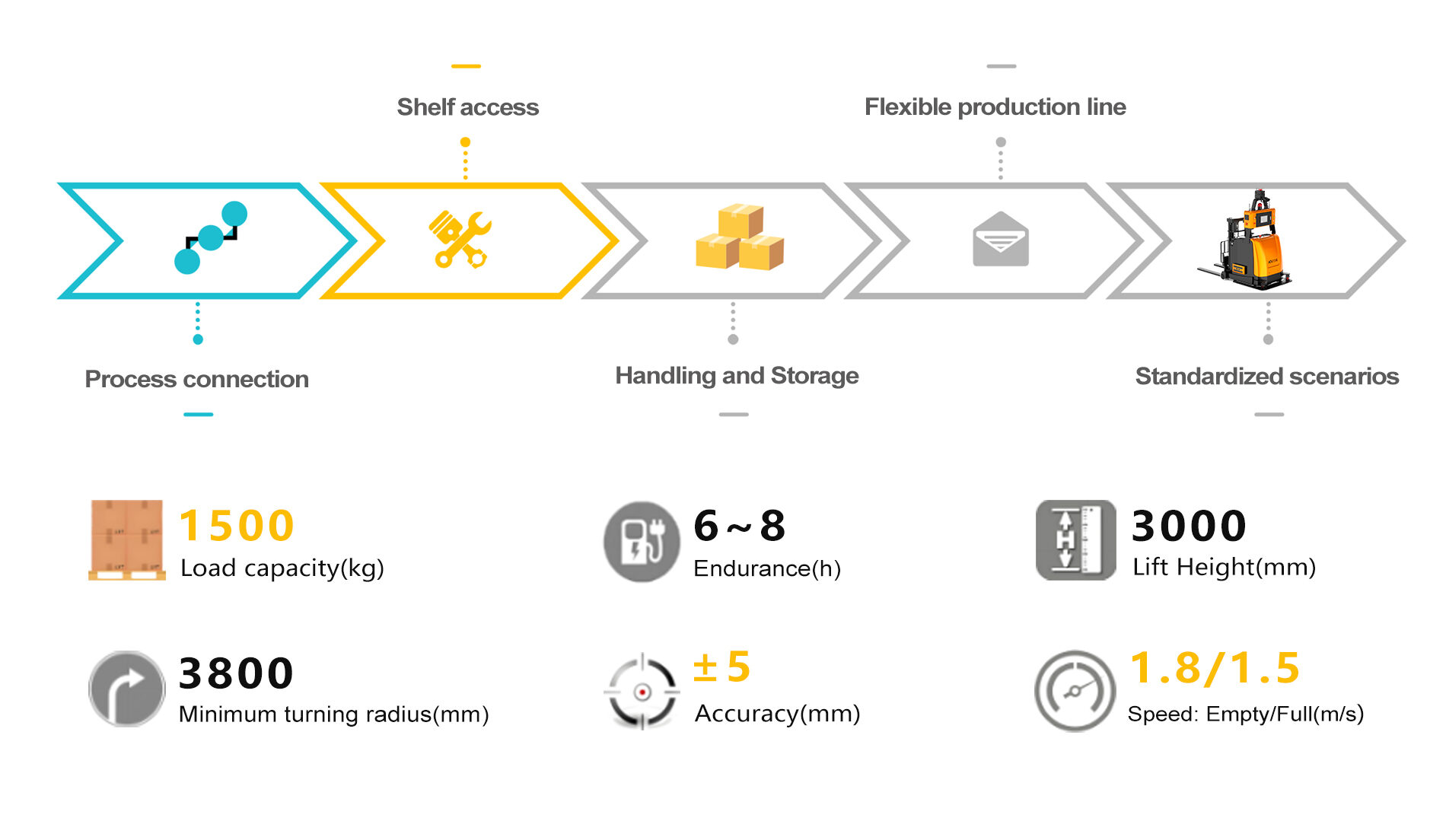

The M15C balanced weight stacking forklift AGV adopts laser SLAM navigation and is designed specifically for automated material handling and stacking in industrial scenarios. It is compatible with double-sided pallets, has a large load capacity, lifting capability, and high precision. It is suitable for material handling, line docking, and warehouse docking scenarios in photovoltaic, mechanical manufacturing, precision manufacturing, textile, food, and other industries.

Parameter

Load: 1500kg

Lifting height: 3000mm

V10KT-800x800.png)