Description

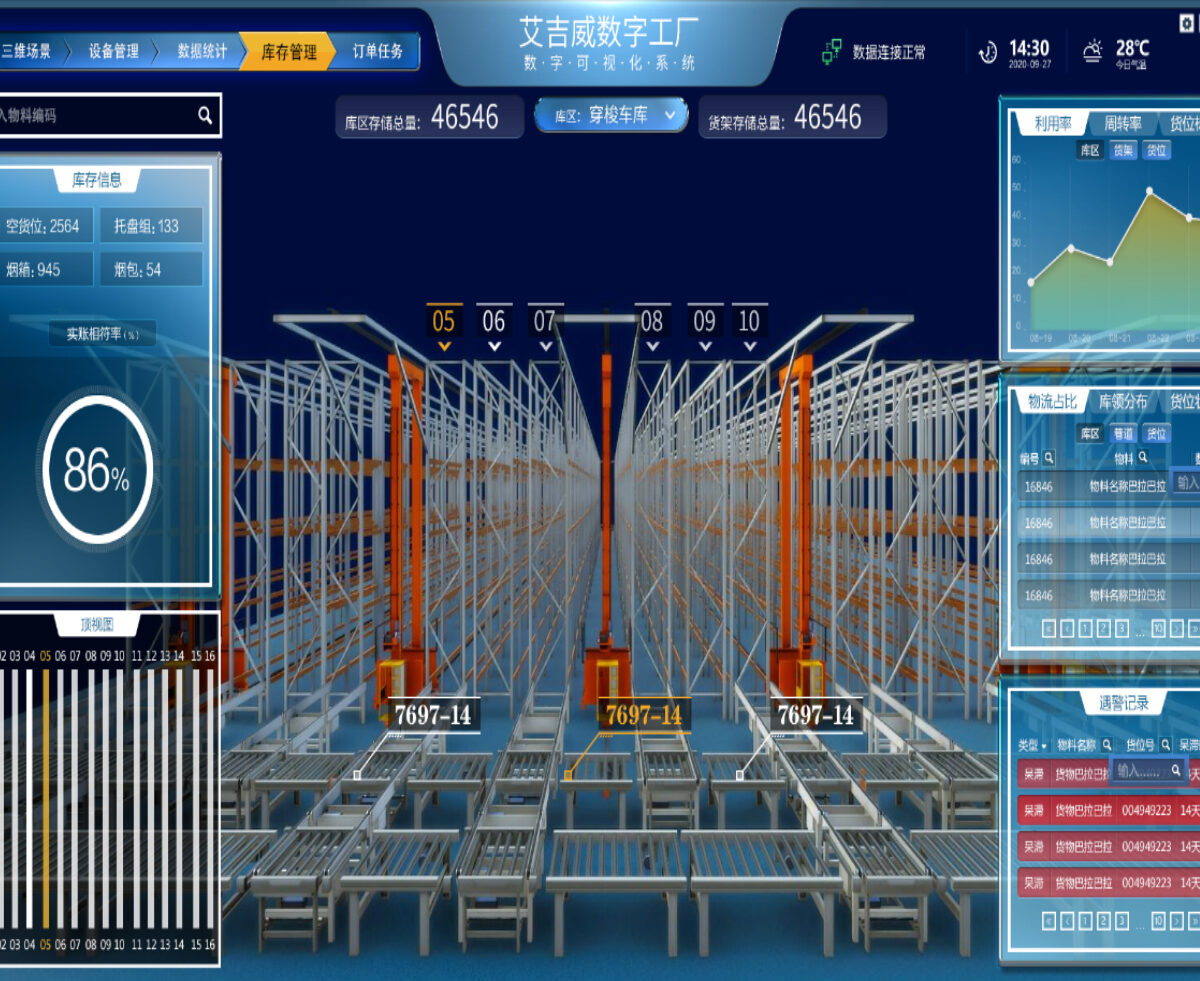

The warehouse control system WCS is located between WMS and underlying logistics equipment, coordinating and scheduling equipment such as AGVs and stackers. Tasks can be allocated reasonably based on WMS instructions, and device operation paths can be intelligently planned. When path conflicts occur, priority can be automatically determined to ensure efficient operation. Assist enterprises in achieving warehouse automation and intelligent management, and improve the efficiency and accuracy of warehouse operations.

Parameter

Multi device control

Improve storage efficiency