Description

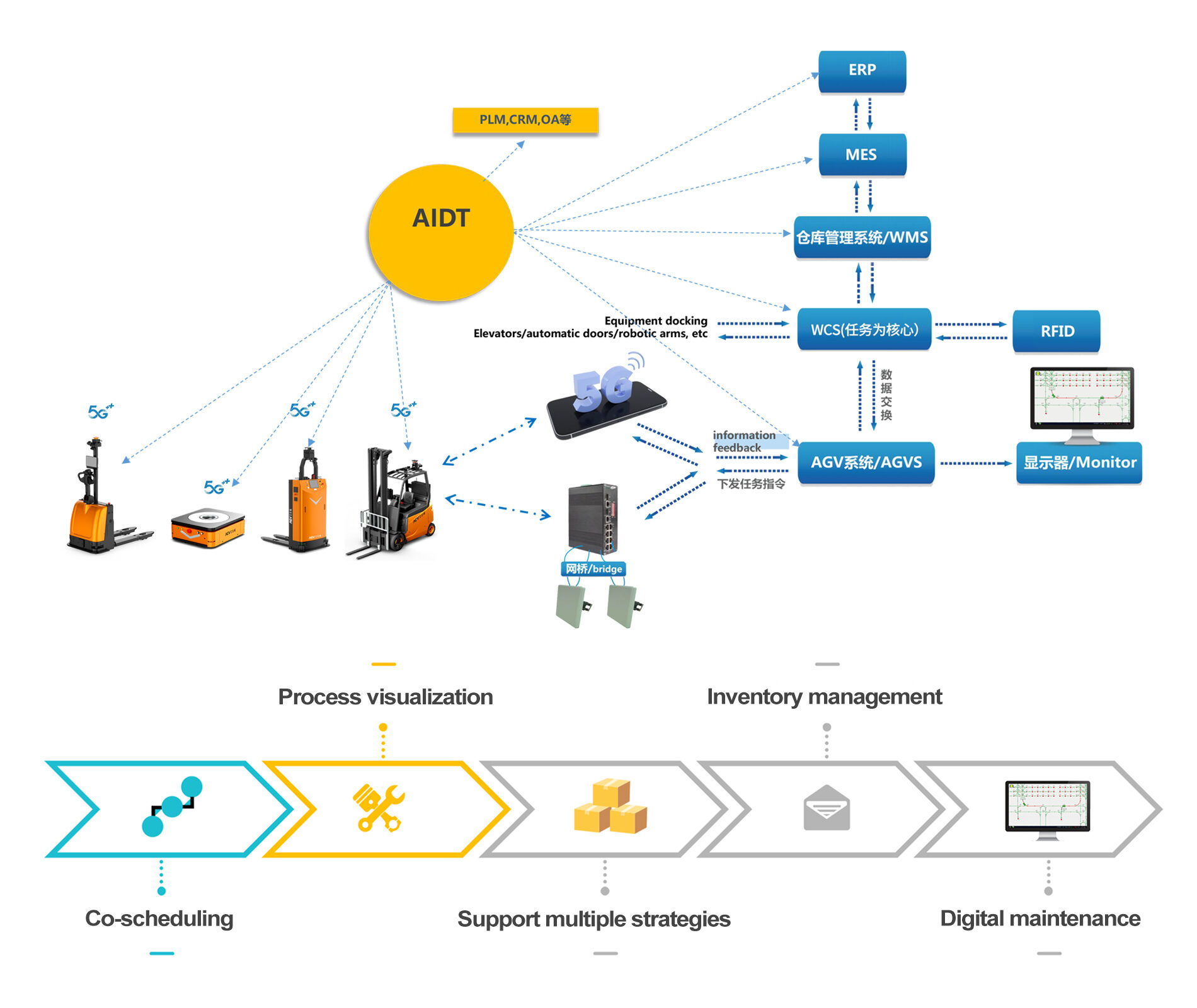

The warehouse control system WMS provides real-time feedback on the usage status of storage locations, accurately schedules the storage and retrieval of various types of goods, and provides reliable data support for the operation of logistics equipment such as AGVS. By cooperating with the equipment control system, it is possible to achieve information-based management of inbound, outbound, and inventory counting processes, comprehensively improving the efficiency of warehouse operations and resource utilization.

Parameter

Inventory management

Improve storage efficiency