Deutsche Post DHL, a subsidiary of the world-renowned mail and logistics group, is facing unprecedented operational challenges for its regional distribution center in Malaysia as an international logistics giant in the face of the booming e-commerce boom in Southeast Asia and the accelerated integration of global supply chains. Rising labor costs, difficulties in recruiting workers under high-intensity operations, increasing customer requirements for order response speed and accuracy, and the urgent need to achieve the company's ESG goals have all formed the core pain points that the company's Malaysian warehouse needs to solve urgently. How to break through the bottleneck and achieve a leap in logistics efficiency and cost control has become a key issue for enterprises.

Project Background

The two phases of the project will improve logistics efficiency, reduce labor costs, make enterprises more advantageous in market competition, and promote the sustainable development of enterprises through the introduction of AGV unmanned forklifts in batches.

Solution

1. The first phase of pilot verification

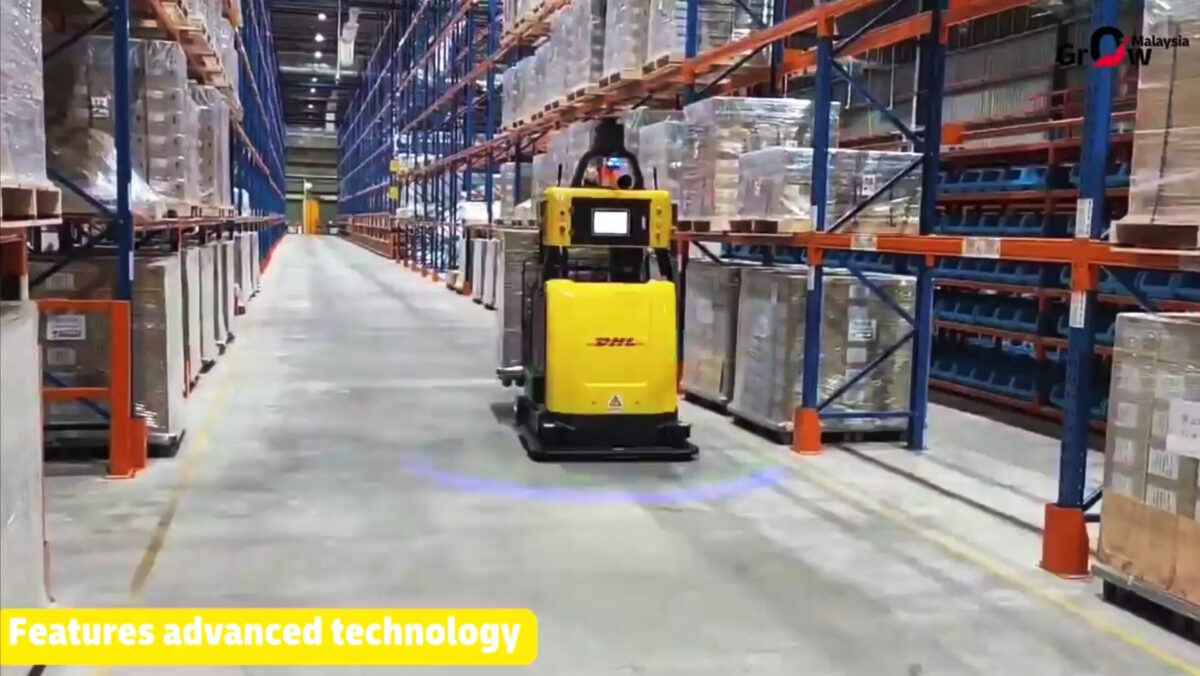

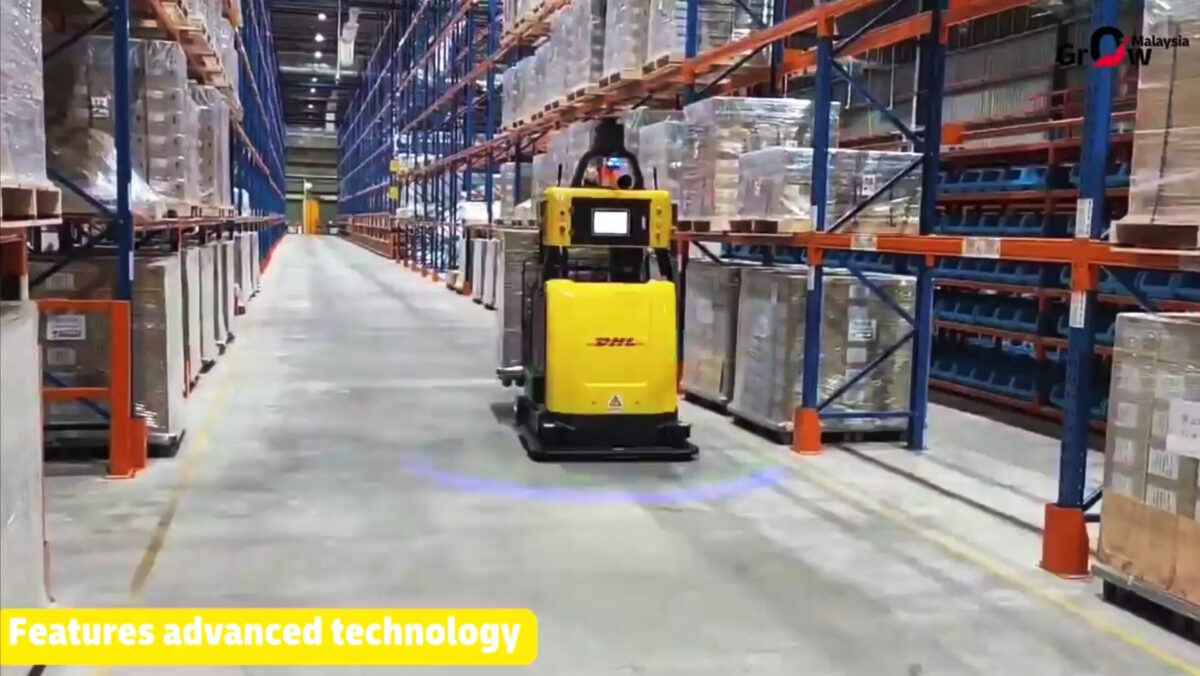

The first batch of "small jacks" series wide outrigger handling type V10KT unmanned forklifts and supporting AGVS dispatching systems were deployed in key operation areas (from the inbound area to the placing and unloading area) to carry out system stability, efficiency improvement and human-machine collaboration ability verification. The model supports manual/automatic mode (press down handle) to switch at will to meet the high operation needs of customers in the manual mixing warehouse.

2. The second phase is fully promoted

Based on the successful experience of the first phase, the unmanned forklift network was extended to high-traffic links such as finished product outbound sorting and cross-regional transfer, so as to realize the automatic coverage of core warehousing processes. The second phase of the project completes the logistics transfer between the warehousing of goods and the storage rack and the outbound station through multiple counterbalanced M15Cs.

3. Seamless integration of intelligent hubs

AGV Tianshu dispatching system (AGVS) is deeply integrated with the enterprise warehouse management system (WMS) to realize automatic issuance of task instructions, optimal vehicle path planning, intelligent traffic management and control, and real-time visual monitoring of operation status.

4. Autonomous navigation and smooth operation

The unmanned forklift equipped with laser SLAM navigation realizes centimeter-level accurate positioning and autonomous obstacle avoidance in complex and dynamic environments, and stably completes the automatic handling, accurate stacking, loading and unloading of palletized goods.

Project benefits

The company's introduction of unmanned forklift projects is of significant value, not only improving the efficiency of logistics operations and greatly reducing the cargo turnover time by virtue of its accurate, efficient and 24×7 operation characteristics, but also reducing operating costs by about 30% by reducing manpower dependence, optimizing energy consumption and maintenance costs. Advanced sensors and obstacle avoidance systems upgrade safety guarantees and reduce accident losses; Operation data helps enterprises achieve refined management, and finally enhances brand image, enhances market competitiveness, and continues to lead in the logistics industry by virtue of the advantages of efficiency, safety and low cost.