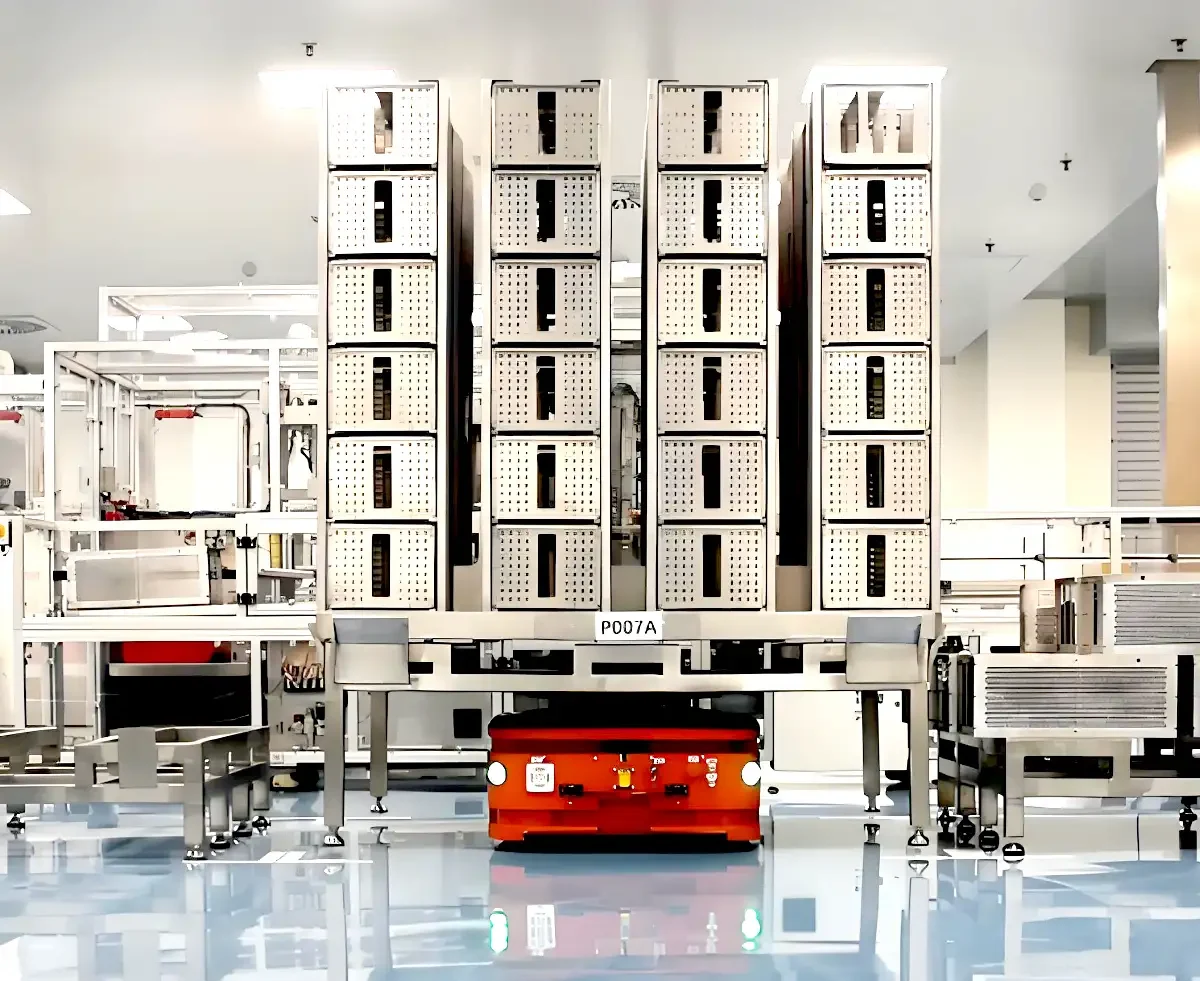

Description

Standard chassis latent AGV, compact and flexible body, multiple driving modes to choose from, with a load of less than 1000kg. Adopting laser SLAM navigation with an accuracy of ± 10mm and equipped with multiple safety protections. It can be integrated with multiple systems, adapt to various scenarios such as daily chemical, pharmaceutical, and mechanical manufacturing, and assist in logistics automation.

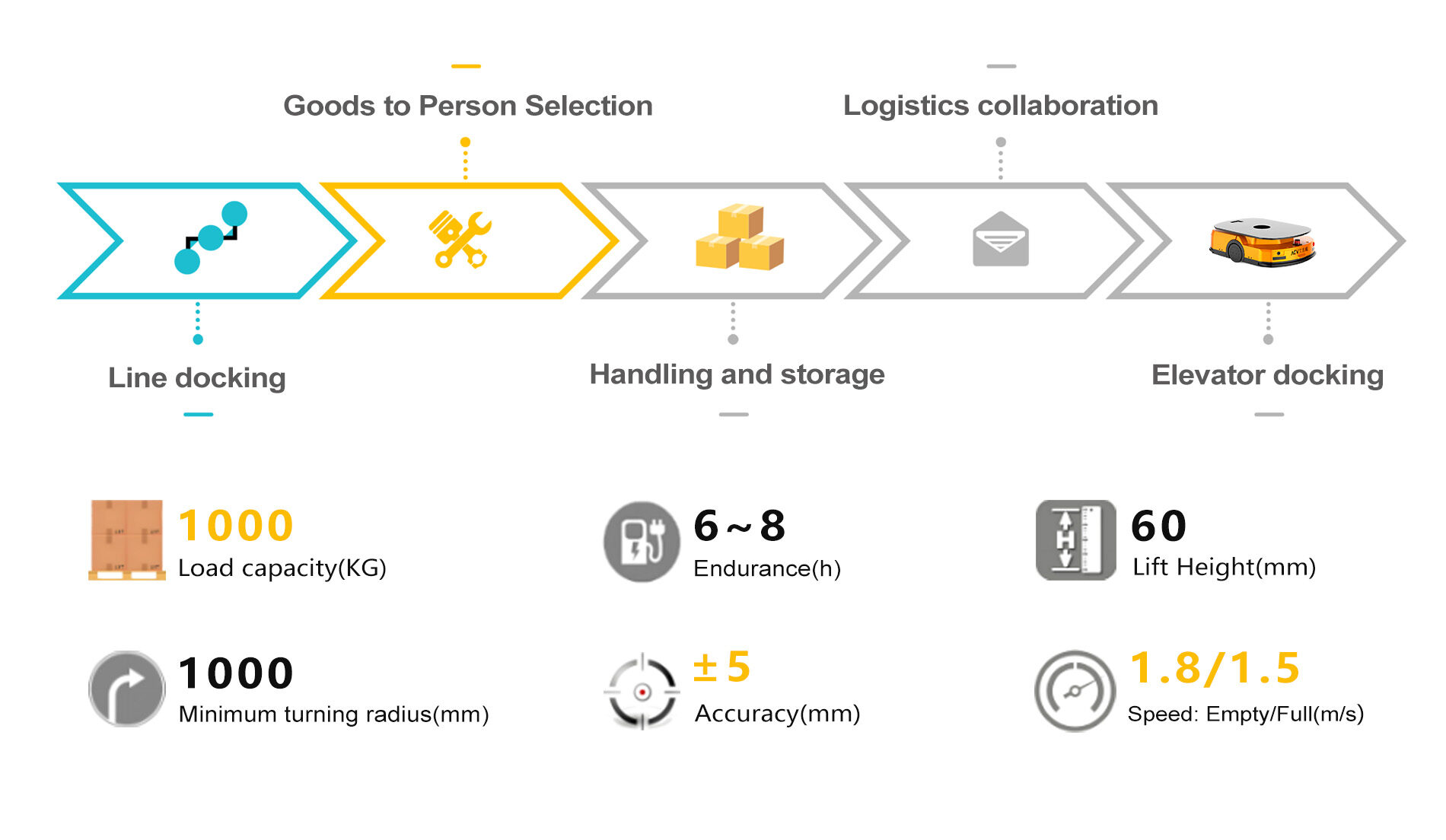

Parameter

Load: 600kg/1000kg

Lift:60mm

V15T-800x800.png)